West London Mental Health NHS Trust

The BHR project is using BIMXtra to enhance the entire project lifecycle from design through procurement, during construction and into the O&M and FM stages.

Introduction

The aim is to provide the client with full asset information upon handover of the project, along with visualisations to allow training and familiarisation.

Kier is leading the project’s BIM requirements and is working with Gilling Dod, WSP Group and Curtins to achieve this aspiration. The consultants are producing models using Autodesk Revit with the underground services being produced in AutoCAD Civil 3D. These models are being imported into BIMXtra utilising bespoke plugin tools created by Clearbox and have enabled the project team to view a federated model and the associated data.

Additionally, Kier has a requirement to track the precast concrete off site manufacture process, which is being managed in BIMXtra with input from the sub contractor and Kier themselves.

Application of BIMXtra

Clearbox provided implementation support on the project for the first 12 months so that advice and guidance could be given through the early stages.

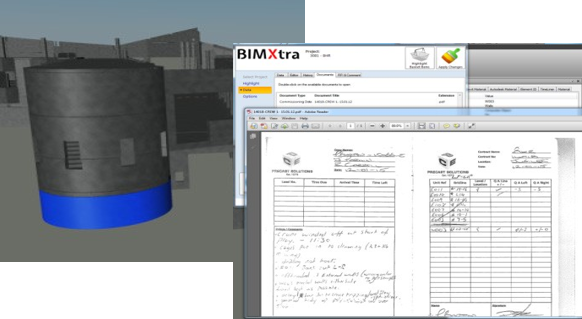

Federated models have been made available to project stakeholders using our viewing engine, Insight, which has been used to assist with design coordination exercises. As the project progressed and as more data was associated to modelled objects, this became accessible within Insight or from the central BIMXtra database. The team has also made use of this model to capture images, which have been used to support requests for information or commenting.

Suppliers of the precast concrete structure, PCE, have also engaged with BIMXtra, completing the design schedules to include test results and dates as well as uploading test certificates, reports and sign off sheets so that these can easily be located and retrieved. This information can be found in the database or when the elements are selected using the federated model in Insight.

Benefits

The input from the subcontractors has been positive with PCE and Kier developing the pre-cast concrete schedule enabling full traceability of the off site manufacture process from design through to sign off on site. The ability to attach documents to components has also enhanced this, making it possible to select a component, either in a schedule or in the 3D model and view the associated data and documentation.

The project is moving toward its aim of having a full asset information model upon project handover. Currently the West London Mental Health NHS Trust and Kier are in discussions to identify the specific requirements to enable this to be achieved and utilised following handover.

This will also open the possibility of using Clearbox’s mobile application to enable users to navigate on site via intelligent drawings associated to their project. The intelligence that sits behind these drawings enables object information to be seen and made use of on site. Simply click on an object within the drawing and information that has been linked via design schedules, operation and maintenance documentation and facilities management requirements are instantly accessible.